Your Custom Text Here

First three images show the initial carving process for the bog oak handle of this gralloching knife. First I cover the handle in surgical tape and draw the design in Sharpie (can't believe it took me 18 years of carving blackwood to figure out that wee trick...), then I cut the outline and remove the background, then cut the interstices and overlaps. Next I skive down the corners of the bands to round them, working with the grain (this is the only part that is traditional push carving - everything else is chip carving). Finally I use a small coarse file to scrape everything smooth, and then sand with 150 grit paper. From here, I will sketch the lines of the grooves which form the cording directly onto the wood in pencil, and carve them one at a time using the same methods...

The fourth image shows the blade hand sanded to 400 grit and given a quick dip in FeCl to check the position of the hardened steel so I can lay out the filework. Once the jimping is done, I'll take the blade to 800 grit...

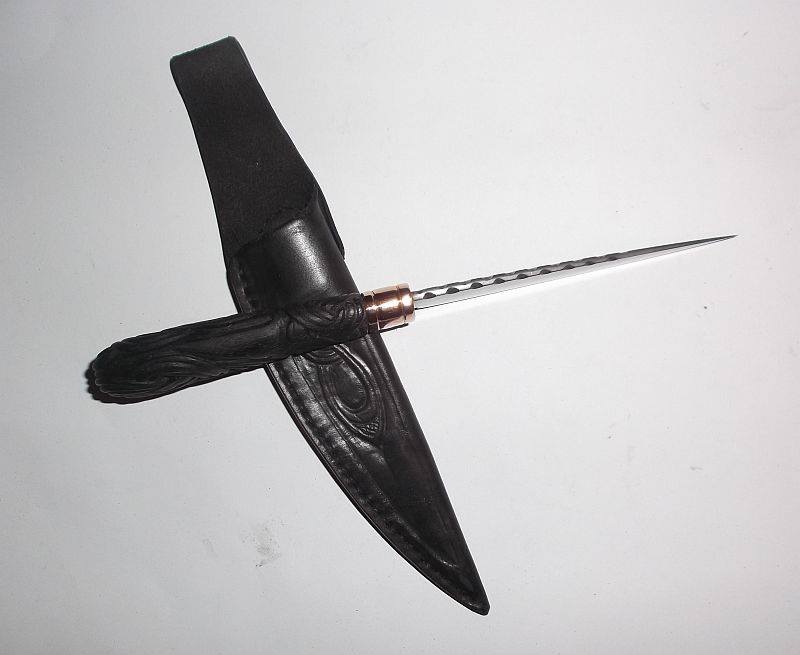

The fifth image shows the carving almost done, while the final three give views of the finished knife and sheath.

First three images show the initial carving process for the bog oak handle of this gralloching knife. First I cover the handle in surgical tape and draw the design in Sharpie (can't believe it took me 18 years of carving blackwood to figure out that wee trick...), then I cut the outline and remove the background, then cut the interstices and overlaps. Next I skive down the corners of the bands to round them, working with the grain (this is the only part that is traditional push carving - everything else is chip carving). Finally I use a small coarse file to scrape everything smooth, and then sand with 150 grit paper. From here, I will sketch the lines of the grooves which form the cording directly onto the wood in pencil, and carve them one at a time using the same methods...

The fourth image shows the blade hand sanded to 400 grit and given a quick dip in FeCl to check the position of the hardened steel so I can lay out the filework. Once the jimping is done, I'll take the blade to 800 grit...

The fifth image shows the carving almost done, while the final three give views of the finished knife and sheath.